- Home

- For the homeowner

- Safety

- Definitions

- Gas furnace

- Some error codes for gas furnaces

- Service sheet for the gas furnace

- gas furnace design

- The gas heat exchanger

- Dangerous conditions in gas furnaces

- Annual service of the gas furnace

- Repair procedures for gas furnaces

- Gas fireplace millivolt systems

- Oil furnace

- Setting gas input

- Quick tips for troubleshooting furnaces

- Troubleshoot

- Operation and troubleshoot furnace by manufacturer

- HVAC war stories blog

- Annual service of an oil furnace

- Oil furnace design

- Oil furnace troubleshoot

- Repair procedures for oil furnaces

- Gas code training

- Piping and connections

- FAG w pilot no fire

- Combustion analysis

- Electric furnace

- Air conditioner

- Refrigeration

- Heat Pump

- Boiler

- Ductwork design and troubleshoot

- Thermostats

- Diagnostic problems

- Tools

- Electric test meters

- Electrical diagram training

- Electrical symbols

- Single and 3 phase power systems

- Electric wiring solutions

- Transformer design and troubleshoot

- Electronic air cleaner

- Blowers and fans design & troubleshoot

- Humidity and humidifiers

- Furnace, Air Conditioner and part manuals

- Electric motors

- Run Capacitors

- Start capacitors

- Troubleshooting the capacitor

- Gas furnace short cycling

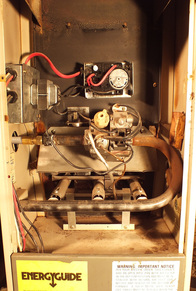

Annual service of the pilot gas furnace

This sheet is a guide to maintaining a gas furnace for long life and no unnecessary failures.

Set the thermostat well above the space temperature.

Check filter condition. Take an overall look at the furnace operation. Listen to the fan motor for abnormal noises. Check the flame. Is it yellow or blue? Gas burner flames should be blue. Is the flame moving up through the furnace normally. Is it lifting off the burners? Is it rolling out the front?

The video below shows an overview of the furnace service.

Check filter condition. Take an overall look at the furnace operation. Listen to the fan motor for abnormal noises. Check the flame. Is it yellow or blue? Gas burner flames should be blue. Is the flame moving up through the furnace normally. Is it lifting off the burners? Is it rolling out the front?

The video below shows an overview of the furnace service.

|

|

|

Above are pics of a pilot assembly, they are configured in different ways but they all provide a flame to light the main burner and a proving method to prove the pilot is lit.

The above pilot is plugged. This pilot does not have enough gas. It is usually a lazy candle like flame. It may have a yellow tip or be completely yellow It may not contact the thermocouple so the thermocouple may cool down enough to drop out on safety.

The video below demonstrates how the pilot safety works and how the pilot is lit and how how to adjust the pilot.

a. Check pilot dropout.

b. Shut off the power to the furnace. Blow out the pilot light with the gas valve in the on position. The valve should close within 3 minutes. You should here a small audible click when dropout occurs. When the valve closes, it should not leak. Try lighting the pilot after it has shut down by leaving the gas valve in the on position and placing a lit match near the pilot light. If the pilot lights, the gas valve is leaking by. If the valve does not close in 3 minutes, or the pilot lights after shutdown, the gas valve must be replaced. This is a flame safety issue, and should not be ignored. I never did.

The video below demonstrates how to check dropout of the pilot safety.

These furnaces are pretty much considered antiques (although they seem to have no antique value). Below is the first in the series of servicing these types of furnaces. They may use the gas chain gas control as in the video, or may have a combination gas valve.

Check the heat exchanger

Above are pics of heat exchangers with rust damage, cracks or overfire damage. When we say check the heat exchanger, we are primarily looking cracks or rusted thru places.

There are a number of ways to check these heat exchangers, but the most common on these older furnaces is by using a flashlight and a mirror.

The video below shows how this is done.

There are a number of ways to check these heat exchangers, but the most common on these older furnaces is by using a flashlight and a mirror.

The video below shows how this is done.

Service the blower

Some of the older furnaces have belt drive blowers. The belt should be checked for cracks. The video below explains how belts are designed and made.

Belt alignment should be checked to reduce abnormal wear.

On fractional horsepower blower systems, the belt tension should be less than drives above 1 horsepower. The video below explains belt tensioning.

Check and clean blower assembly. The above belt drive blower should have the motor removed and the blower cleaned. The below blower is direct drive meaning the blower moves at the same speed as the motor. The blower wheel needs to be removed and cleaned separately from the motor. It should be cleaned with detergent. The motor must be kept dry. This involves completely disassembling the blower assembly.

The video below shows the cleaning of a very dirty blower assembly.

Continuing the service the burners need to be cleaned. They should be removed and the slots in the burners cleaned of rust and dirt. The pilot assembly should also be cleaned. The video below covers these operations.

The last part of the service is to fire off, check for gas leaks, adjust burner primary air and check cycling of the entire furnace.

The video below shows how to do this.

The video below shows how to do this.

As a recap, all safeties need to be tested, the furnace should be cycled completely through a cycle, general cleanup done and when leaving the furnace room the furnace should be running.