- Home

- For the homeowner

- Safety

- Definitions

- Gas furnace

- Some error codes for gas furnaces

- Service sheet for the gas furnace

- gas furnace design

- The gas heat exchanger

- Dangerous conditions in gas furnaces

- Annual service of the gas furnace

- Repair procedures for gas furnaces

- Gas fireplace millivolt systems

- Oil furnace

- Setting gas input

- Quick tips for troubleshooting furnaces

- Troubleshoot

- Operation and troubleshoot furnace by manufacturer

- HVAC war stories blog

- Annual service of an oil furnace

- Oil furnace design

- Oil furnace troubleshoot

- Repair procedures for oil furnaces

- Gas code training

- Piping and connections

- FAG w pilot no fire

- Combustion analysis

- Electric furnace

- Air conditioner

- Refrigeration

- Heat Pump

- Boiler

- Ductwork design and troubleshoot

- Thermostats

- Diagnostic problems

- Tools

- Electric test meters

- Electrical diagram training

- Electrical symbols

- Single and 3 phase power systems

- Electric wiring solutions

- Transformer design and troubleshoot

- Electronic air cleaner

- Blowers and fans design & troubleshoot

- Humidity and humidifiers

- Furnace, Air Conditioner and part manuals

- Electric motors

- Run Capacitors

- Start capacitors

- Troubleshooting the capacitor

- Gas furnace short cycling

Gas code training

The file below is the International Fuel Gas Code for 2012

| icc.ifgc.2012.pdf | |

| File Size: | 28517 kb |

| File Type: | |

What the code covers

The International Fuel Gas Code (IFGC) is used in most areas in the USA.

The reason for this code is to establish minimum installation standards for natural gas and propane systems and the accompanying accessories.

The scope of the code is not to change existing installations of equipment.

This means if equipment has been installed before this code was adapted, it does not have to be replaced. However, if it is replaced, the equipment must be installed according to these codes.

To understand this code, you need to know that it is not the code for the manufacture of equipment. Equipment is manufactured to listing standards established for that type of equipment.

As the manufacturer has tested and had the equipment listed by an approval agency, (UL, AGA), the installation instructions for the equipment will supersede the IFGC code when the two conflict.

State and local codes can be more restrictive than the IFGC, but not less.

Authority having jurisdiction

The definition is the agency that has been given the responsibility to inspect and enforce the code.

Inspectors are there to be sure the code is followed. However, the inspectors cannot be held liable for damage or injuries incurred through discharge of their duties.

Code officials have the authority to enter, for inspection purposes, any building to do their job.

Some definitions

Access to

An appliance that can be easily accessed by removing a panel

Approved

Acceptable to the authority having jurisdiction.

Used materials.

Used materials cannot be reused unless they come up to new materials standards.

Permits

Installing, altering, repair, replace, etc of equipment covered by this code triggers the need for application for a permit.

Portable heating appliances are not covered by this code.

Replacement of minor parts that do not alter the operation beyond manufacturer specifications or make the equipment unsafe do not require a permit.

Getting a permit does not mean it is a permit to violate this code.

Inspections and testing.

Underground installations of piping shall be left open for inspection and testing.

Piping inside walls, etc must be left open for inspection.

Unsafe installations

If an installation is considered unsafe by the authority having jurisdiction, it shall not be used, and must be repaired, removed or replaced.

General regulations

Appliance fuel conversion

In order to change fuel in an appliance, instructions for the change must be included with the manufacturer instructions with the appliance or by the serving gas supplier.

More coming

The reason for this code is to establish minimum installation standards for natural gas and propane systems and the accompanying accessories.

The scope of the code is not to change existing installations of equipment.

This means if equipment has been installed before this code was adapted, it does not have to be replaced. However, if it is replaced, the equipment must be installed according to these codes.

To understand this code, you need to know that it is not the code for the manufacture of equipment. Equipment is manufactured to listing standards established for that type of equipment.

As the manufacturer has tested and had the equipment listed by an approval agency, (UL, AGA), the installation instructions for the equipment will supersede the IFGC code when the two conflict.

State and local codes can be more restrictive than the IFGC, but not less.

Authority having jurisdiction

The definition is the agency that has been given the responsibility to inspect and enforce the code.

Inspectors are there to be sure the code is followed. However, the inspectors cannot be held liable for damage or injuries incurred through discharge of their duties.

Code officials have the authority to enter, for inspection purposes, any building to do their job.

Some definitions

Access to

An appliance that can be easily accessed by removing a panel

Approved

Acceptable to the authority having jurisdiction.

Used materials.

Used materials cannot be reused unless they come up to new materials standards.

Permits

Installing, altering, repair, replace, etc of equipment covered by this code triggers the need for application for a permit.

Portable heating appliances are not covered by this code.

Replacement of minor parts that do not alter the operation beyond manufacturer specifications or make the equipment unsafe do not require a permit.

Getting a permit does not mean it is a permit to violate this code.

Inspections and testing.

Underground installations of piping shall be left open for inspection and testing.

Piping inside walls, etc must be left open for inspection.

Unsafe installations

If an installation is considered unsafe by the authority having jurisdiction, it shall not be used, and must be repaired, removed or replaced.

General regulations

Appliance fuel conversion

In order to change fuel in an appliance, instructions for the change must be included with the manufacturer instructions with the appliance or by the serving gas supplier.

More coming

Most areas subscribe to some sort of minimum standards for the installation of all gas appliances.

For many areas, the International Fuel Gas Code or IFGC is that standard.

When installing the supply piping for natural gas or propane appliances, there are specific sizes and methods that are considered the minimum for safe operation.

Below is a training video meant for use with the IFGC for sizing wrought iron or "black pipe" for use with natural gas.

For many areas, the International Fuel Gas Code or IFGC is that standard.

When installing the supply piping for natural gas or propane appliances, there are specific sizes and methods that are considered the minimum for safe operation.

Below is a training video meant for use with the IFGC for sizing wrought iron or "black pipe" for use with natural gas.

The file below is the 2012 International Fuel Gas Code that is used for the above video.

| icc.ifgc.2012.pdf | |

| File Size: | 28517 kb |

| File Type: | |

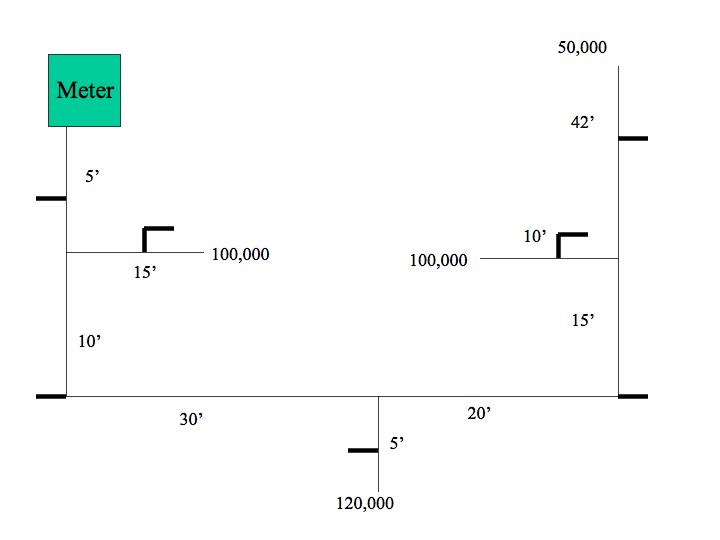

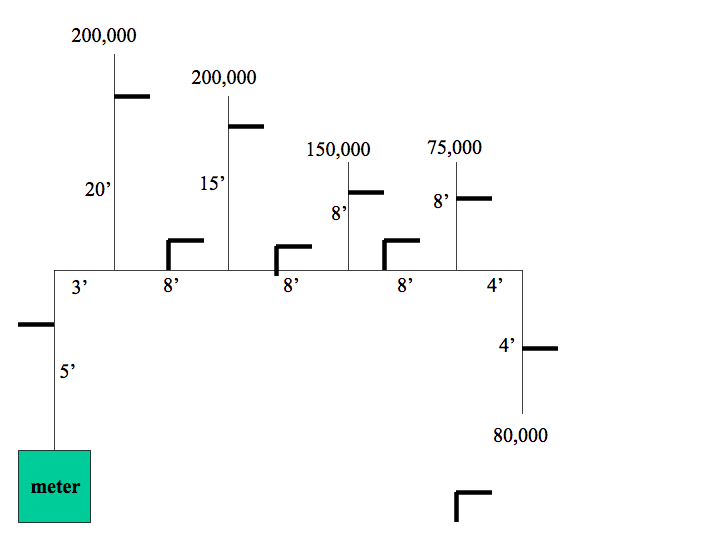

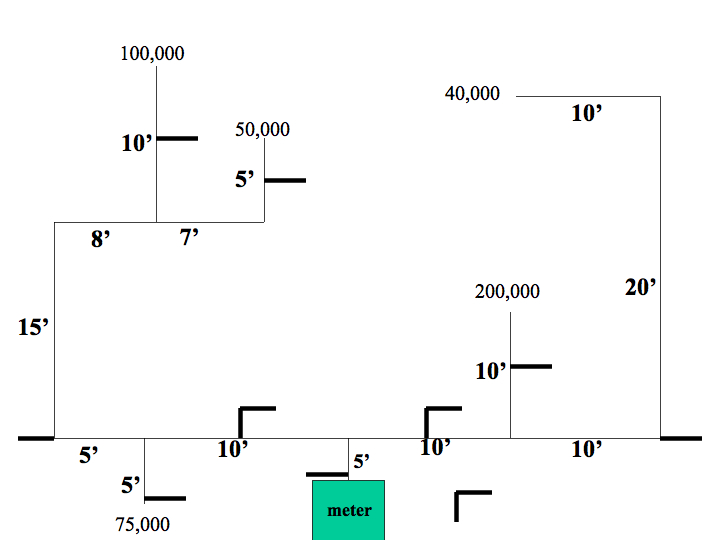

The exercises below may help you with using the IFGC code book to calculate pipe sizing.

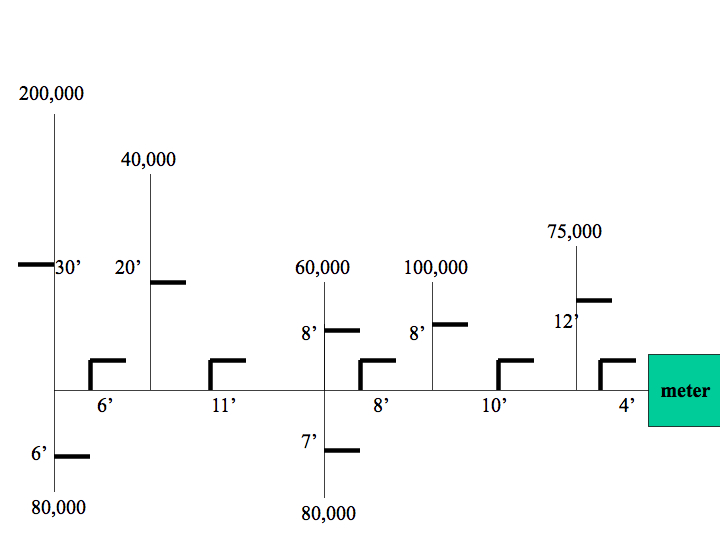

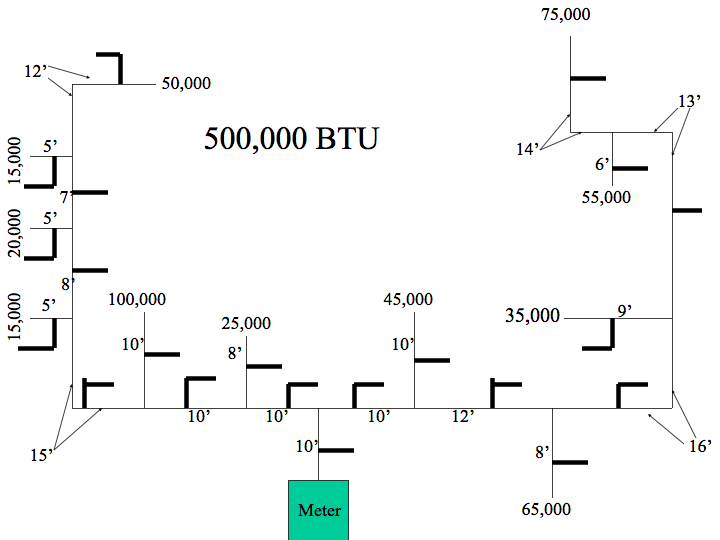

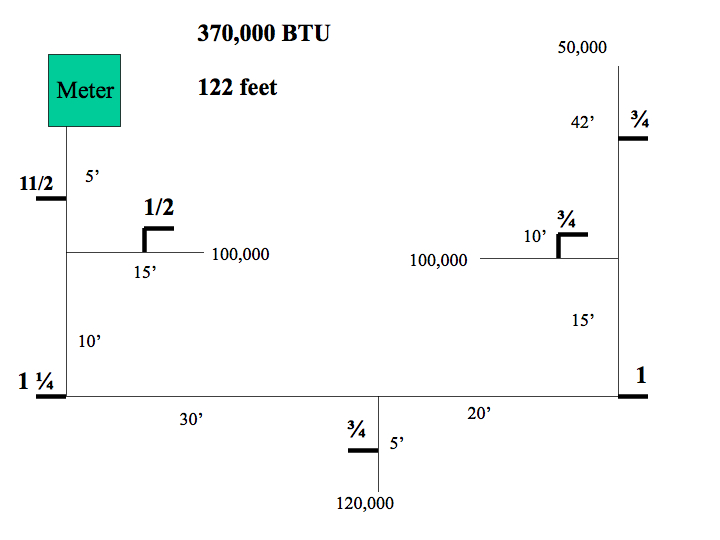

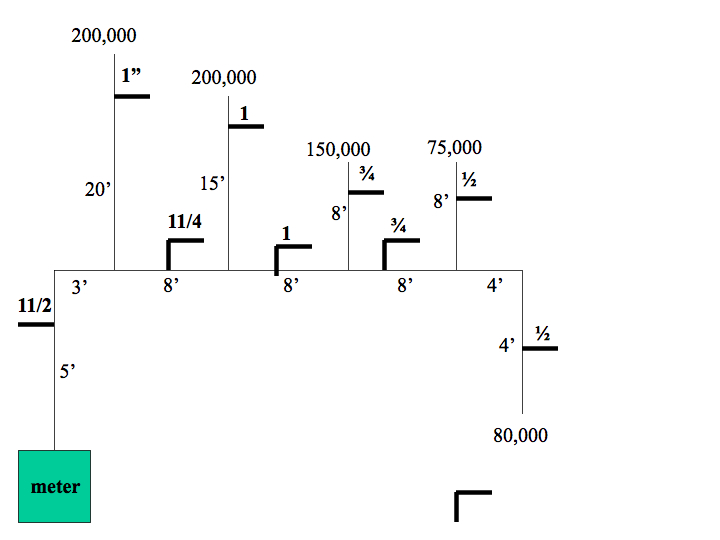

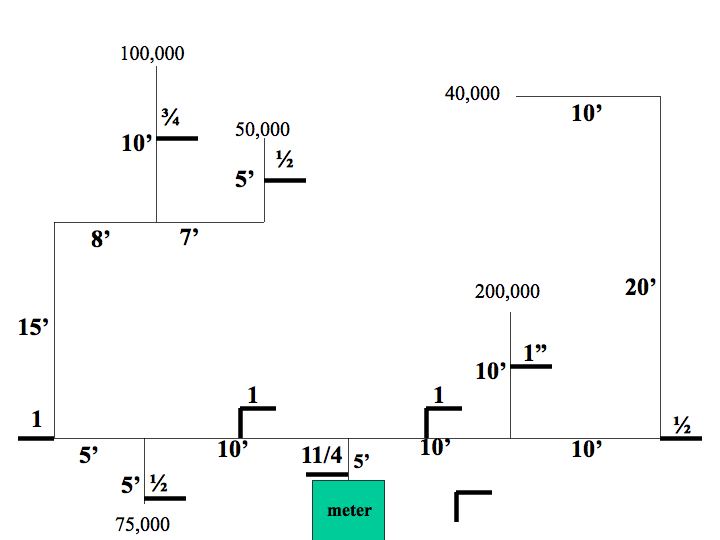

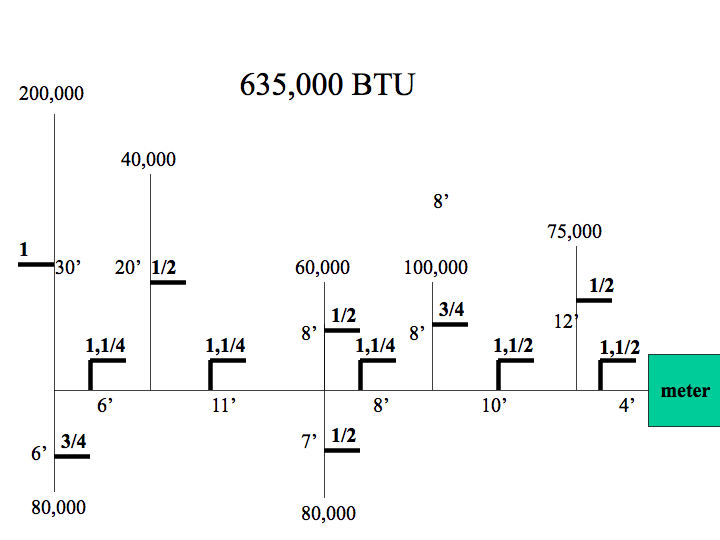

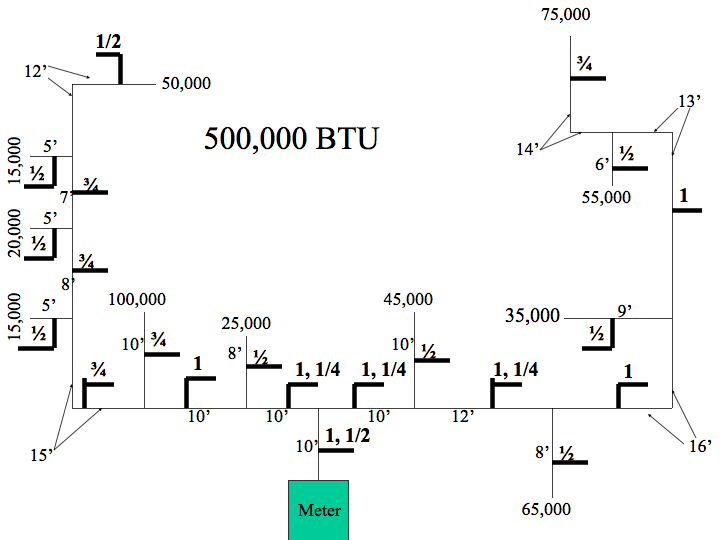

The light lines are the pipe. The length is from one tee or ell to the next. The heavy lines are to write your pipe size. Answers are below the exercises.

The light lines are the pipe. The length is from one tee or ell to the next. The heavy lines are to write your pipe size. Answers are below the exercises.

Exercise #1

Exercise #2

Exercise #3

Exercise #4

Exercise #5

Answer to Exercise #1

Answer to exercise #2

Answer to exercise #3

Answer to exercise #4

Answer to exercise #5

Venting

The means by which burned gasses are moved from inside of a structure to outside.

Venting system:

Mechanical draft venting system

A venting system designed to remove flue gasses by mechanical means, that consists of an induced draft portion under negative pressure or a forced draft portion under positive pressure.

Forced draft venting system

A portion of a venting system using mechanical means (fan) under positive pressure.

Induced draft venting system

A portion of a venting system using mechanical means (fan) to remove vent gasses under negative pressure.

Natural draft venting system

A venting system using natural draft to remove vent gasses under negative pressure.

The means by which burned gasses are moved from inside of a structure to outside.

Venting system:

Mechanical draft venting system

A venting system designed to remove flue gasses by mechanical means, that consists of an induced draft portion under negative pressure or a forced draft portion under positive pressure.

Forced draft venting system

A portion of a venting system using mechanical means (fan) under positive pressure.

Induced draft venting system

A portion of a venting system using mechanical means (fan) to remove vent gasses under negative pressure.

Natural draft venting system

A venting system using natural draft to remove vent gasses under negative pressure.