- Home

- For the homeowner

- Safety

- Definitions

- Gas furnace

- Some error codes for gas furnaces

- Service sheet for the gas furnace

- gas furnace design

- The gas heat exchanger

- Dangerous conditions in gas furnaces

- Annual service of the gas furnace

- Repair procedures for gas furnaces

- Gas fireplace millivolt systems

- Oil furnace

- Setting gas input

- Quick tips for troubleshooting furnaces

- Troubleshoot

- Operation and troubleshoot furnace by manufacturer

- HVAC war stories blog

- Annual service of an oil furnace

- Oil furnace design

- Oil furnace troubleshoot

- Repair procedures for oil furnaces

- Gas code training

- Piping and connections

- FAG w pilot no fire

- Combustion analysis

- Electric furnace

- Air conditioner

- Refrigeration

- Heat Pump

- Boiler

- Ductwork design and troubleshoot

- Thermostats

- Diagnostic problems

- Tools

- Electric test meters

- Electrical diagram training

- Electrical symbols

- Single and 3 phase power systems

- Electric wiring solutions

- Transformer design and troubleshoot

- Electronic air cleaner

- Blowers and fans design & troubleshoot

- Humidity and humidifiers

- Furnace, Air Conditioner and part manuals

- Electric motors

- Run Capacitors

- Start capacitors

- Troubleshooting the capacitor

- Gas furnace short cycling

Hot water boiler design

|

|

|

Boilers heat water either to produce steam or hot water. In either case, the temperatures are high enough to cause scalding. Boilers may contain high pressures that could cause explosion. In addition, the fuels can be explosive and the electric power used to control the boiler is lethal. Do not proceed if you are not confident of your abilities.

The basics

The hot water boiler does not boil water. It warms the water up to a maximum of 220 degreesF 104.4C. If you are wondering why the water does not boil, it is under pressure. The pressure increases the boiling temperature of the water. The water is then pumped throughout the structure to terminal units (radiators, baseboards, even the floor or ceiling) where the heat is transferred to the structure.

That is a simple definition of what sometimes seems to be a very complicated heating system.

That is a simple definition of what sometimes seems to be a very complicated heating system.

Why water instead of air

Why should you add the complication of heating water when all I want to do is be surrounded by warm air?

Water absorbs more sensible heat than any other substance per pound. It takes 1 BTU to warm 1 pound of water 1 degree F. (One calorie to warm one kilogram of water 1 degree C). Due to this capacity, very small amounts of water can heat very large areas. Rather than using large air ducts that take up large amounts of space, much smaller pipes can be used.

Where a large amount of heat is needed to pass through a small area, a boiler is used.

Water is very efficient for warming floors or walls. Warm objects in a room will make a cooler room feel warmer.

Water absorbs more sensible heat than any other substance per pound. It takes 1 BTU to warm 1 pound of water 1 degree F. (One calorie to warm one kilogram of water 1 degree C). Due to this capacity, very small amounts of water can heat very large areas. Rather than using large air ducts that take up large amounts of space, much smaller pipes can be used.

Where a large amount of heat is needed to pass through a small area, a boiler is used.

Water is very efficient for warming floors or walls. Warm objects in a room will make a cooler room feel warmer.

Types of Boilers

The cast iron boilerThe cast iron boiler is probably the longest lasting of all boilers.

Water is passed through the outer jacket and heat from combustion of fuel passes through inner passageways and water is warmed as it passes through. Cast iron boilers are usually made in sections like on the left. As you add more sections, you increase the capacity of the boiler. |

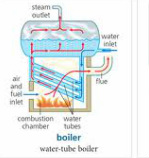

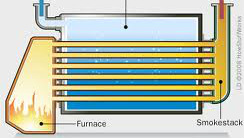

Water tube boilers

Fire tube boilers

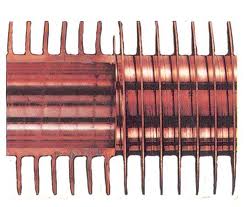

Copper boilers

|

A copper boiler is a water tube boiler. On the left are the tubes used in a copper boiler. The hot gasses pass across the fins and the fins transfer heat to the water inside.

These boilers are often used in domestic hot water applications. These boilers are not as long lasting as cast iron or steel. Returning water temperature cannot be below 110 degrees F (43.3 C) because they will condense water on the fins. The condensed water has a high percentage of acid which corrodes the copper. In any case, they are not popular in residential boiler systems. |

Modern boiler systems

In recent years, boiler technology has moved towards different materials and controls for hot water boilers. Materials like aluminum and stainless steel are replacing the cast iron and copper boilers.

Also boilers are much smaller than in earlier years. Older cast iron units may have contained several gallons of water. This meant that in the off cycle there may be quite a lot of hot water in the boiler. This could mean the heat could be lost up the vent. Also these boilers were slow to heat up and could not respond fast to temperature changes.

The newer styles have less than 1 gallon of water in them and so can heat very quickly. They also have more sophisticated controls both for flame safety and hot water temperature control that adjusts for outside temperature.

Below are some examples of newer style boilers. I have not seen a lot of problems with these boilers but in the 1980s there were some stainless steel low water volume boilers and the failure rate was very high. Only time will tell if these boilers will stand the test of time that the cast iron boilers already have.

Also boilers are much smaller than in earlier years. Older cast iron units may have contained several gallons of water. This meant that in the off cycle there may be quite a lot of hot water in the boiler. This could mean the heat could be lost up the vent. Also these boilers were slow to heat up and could not respond fast to temperature changes.

The newer styles have less than 1 gallon of water in them and so can heat very quickly. They also have more sophisticated controls both for flame safety and hot water temperature control that adjusts for outside temperature.

Below are some examples of newer style boilers. I have not seen a lot of problems with these boilers but in the 1980s there were some stainless steel low water volume boilers and the failure rate was very high. Only time will tell if these boilers will stand the test of time that the cast iron boilers already have.

Types of terminal units

Lets look at some of the options available to hot water.

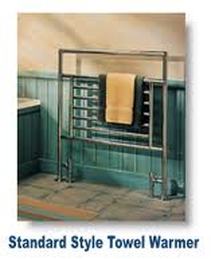

On the left is a towel warmer that not only keeps towels warm but is the terminal unit to warm the bathroom.

|

On the left heat pipes are coiled in the floor and thinset concrete is poured around them to make the subfloor.

Hot water is pumped through the pipes to warm the floor. The value of warm floors is that if your feet are warm a lower temperature in the structure will seem warmer. Also drafts from opened doors will not cool the structure as much. |

|

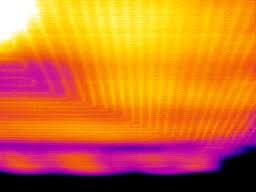

On the left is an infared picture of a radiant ceiling panel using hot water pipes. This way of using hot water panels was used in the 1960s. The panels gave off radiant heat.

This method is seldom used anymore due to the inefficiency of using panels in the ceiling, the higher temperature needed and lack of warmth under tables etc. |

The central boiler can be used to heat domestic hot water in addition to heating the space.

One of the ways to accomplish this is to use a tank with a heat exchanger inside that transfers heat from the boiler water to the water in the tank. The video below shows how this tank works.

One of the ways to accomplish this is to use a tank with a heat exchanger inside that transfers heat from the boiler water to the water in the tank. The video below shows how this tank works.