- Home

- For the homeowner

- Safety

- Definitions

- Gas furnace

- Some error codes for gas furnaces

- Service sheet for the gas furnace

- gas furnace design

- The gas heat exchanger

- Dangerous conditions in gas furnaces

- Annual service of the gas furnace

- Repair procedures for gas furnaces

- Gas fireplace millivolt systems

- Oil furnace

- Setting gas input

- Quick tips for troubleshooting furnaces

- Troubleshoot

- Operation and troubleshoot furnace by manufacturer

- HVAC war stories blog

- Annual service of an oil furnace

- Oil furnace design

- Oil furnace troubleshoot

- Repair procedures for oil furnaces

- Gas code training

- Piping and connections

- FAG w pilot no fire

- Combustion analysis

- Electric furnace

- Air conditioner

- Refrigeration

- Heat Pump

- Boiler

- Ductwork design and troubleshoot

- Thermostats

- Diagnostic problems

- Tools

- Electric test meters

- Electrical diagram training

- Electrical symbols

- Single and 3 phase power systems

- Electric wiring solutions

- Transformer design and troubleshoot

- Electronic air cleaner

- Blowers and fans design & troubleshoot

- Humidity and humidifiers

- Furnace, Air Conditioner and part manuals

- Electric motors

- Run Capacitors

- Start capacitors

- Troubleshooting the capacitor

- Gas furnace short cycling

Oil furnace troubleshoot

|

|

|

Oil furnaces use a flammable fuel. leaks left can cause fires. Things like puffback are usually not devastating explosions but can cause a fire or extensive property damage. There are also lethal voltages involved. Know your limits.

First, lets look at the components of the oil furnace. Components on left are as follows: Top black pipe, smoke pipe.

Below the smoke pipe the three round caps cover (center) inspection cover for flame viewing, the 2 covers on either side are for heat exchanger cleaning.

Fan and limit switch is on the left.

Burner assembly lower center.

Circulating fan underneath.

If your furnace will not heat, first check the home page.

If you have no luck, and the thermostat is calling for heat, do not immediately press any reset button.

First remove the covers. Are there any oil leaks? If so, find and repair the leaks. They could cause a fire.

Is there a smell of burned oil? If so, there may be a draft problem. Check here. Is there a smell of unburned oil? This could be an indication of a failure to ignite.

Careful here. If the burner has failed to ignite, there could be unburned oil in the combustion chamber. The video below gives a demonstration of an oil furnace with an open combustion chamber igniting after going through 2 cycles where the oil did not ignite. The unburned oil in the chamber may ignite explosively. With the top on the combustion chamber, the puffback will come out the inspection door with possibly a sooty mess or a fire.

Many times if there is a small amount of unburned oil in the chamber, it will light more or less normally, but will burn after the burner has shut off.

If the reset has been pushed several times, you could have an out of control fire.

Below the smoke pipe the three round caps cover (center) inspection cover for flame viewing, the 2 covers on either side are for heat exchanger cleaning.

Fan and limit switch is on the left.

Burner assembly lower center.

Circulating fan underneath.

If your furnace will not heat, first check the home page.

If you have no luck, and the thermostat is calling for heat, do not immediately press any reset button.

First remove the covers. Are there any oil leaks? If so, find and repair the leaks. They could cause a fire.

Is there a smell of burned oil? If so, there may be a draft problem. Check here. Is there a smell of unburned oil? This could be an indication of a failure to ignite.

Careful here. If the burner has failed to ignite, there could be unburned oil in the combustion chamber. The video below gives a demonstration of an oil furnace with an open combustion chamber igniting after going through 2 cycles where the oil did not ignite. The unburned oil in the chamber may ignite explosively. With the top on the combustion chamber, the puffback will come out the inspection door with possibly a sooty mess or a fire.

Many times if there is a small amount of unburned oil in the chamber, it will light more or less normally, but will burn after the burner has shut off.

If the reset has been pushed several times, you could have an out of control fire.

Does the burner do anything at all? After checking for oil leaks, If the burner hums or does nothing at all, check to see if there is power to the furnace. Locate the power switch, be sure it is on. Check all breakers or fuses in the circuit. Once you know where the power switch is, reset the primary control. The video below may help.

The barometric draft damper

Is there black soot around the inspection cover? Soot inside when the cover is removed? Next look at the damper. open it and look inside. Is it black and have heavy soot deposits?

If so click here

If the control has been reset many times, you will need to check the combustion chamber for unburned oil. This means either viewing with a mirror or using some other method to find out if there is unburned oil in the combustion chamber. DO NOT fire off a unit if that has large amounts of unburned oil in the combustion chamber. Once the fire is established, it is very hard to put out and could result in an uncontrollable fire. If any of these things are observed, proceed carefully.

If so click here

If the control has been reset many times, you will need to check the combustion chamber for unburned oil. This means either viewing with a mirror or using some other method to find out if there is unburned oil in the combustion chamber. DO NOT fire off a unit if that has large amounts of unburned oil in the combustion chamber. Once the fire is established, it is very hard to put out and could result in an uncontrollable fire. If any of these things are observed, proceed carefully.

If oil is present and the burner does not light:

Ok lets assume none of the above exist. If the pump motor runs, but no flame is established, shut down the power switch. Do not open the inspection door during the trial for ignition if flame is not established. Oil furnaces usually choose the time that you open the door to start, which will give you a face full of soot!

Once the power switch is shut off, open the inspection door. Is there a fog of oil droplets in the chamber? If so, the oil is not igniting. If there is no indication of oil in the combustion chamber, click here

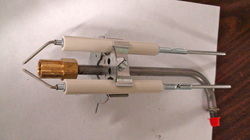

On the left is a oil furnace transformer. It is capable of producing 10-20,000 volts. Open the top of the burner. The contact springs as on left are the terminals. With the burner motor running, short the terminals with a screwdriver, then draw the screwdriver away from one terminal. The spark should be heavy and thick and should lengthen to approx 3/4".

If no spark is present or it is very weak, clean the insulators just below the springs. If no help, the transformer has failed.

If spark is present, the problem may be in the electrodes or the spark gap at the end of the electrodes.

The following videos may help understand where to find the components and the procedures to test them. Troubleshooting will continue below the videos.

Once the power switch is shut off, open the inspection door. Is there a fog of oil droplets in the chamber? If so, the oil is not igniting. If there is no indication of oil in the combustion chamber, click here

On the left is a oil furnace transformer. It is capable of producing 10-20,000 volts. Open the top of the burner. The contact springs as on left are the terminals. With the burner motor running, short the terminals with a screwdriver, then draw the screwdriver away from one terminal. The spark should be heavy and thick and should lengthen to approx 3/4".

If no spark is present or it is very weak, clean the insulators just below the springs. If no help, the transformer has failed.

If spark is present, the problem may be in the electrodes or the spark gap at the end of the electrodes.

The following videos may help understand where to find the components and the procedures to test them. Troubleshooting will continue below the videos.

Above we have some tests of the spark that ignites the flame. To see how it operates when the burner assembly is installed, the video below may help.

The gun assembly

The electrodes are placed directly above the nozzle. The electrode ceramics should be inspected for cracks. If the electrodes are adjusted incorrectly they may contact the head of the burner. Also if the gun assembly is adjusted incorrectly, the nozzle spray may contact the burner head. If so the oil will not burn completely. Soot will build up and coke deposits will short out the spark.

When setting up the gun assembly look at the annual service click here

Home

When setting up the gun assembly look at the annual service click here

Home

The videos below show how to proceed when troubleshooting and may give you a method to follow to find the problem.