- Home

- For the homeowner

- Safety

- Definitions

- Gas furnace

- Some error codes for gas furnaces

- Service sheet for the gas furnace

- gas furnace design

- The gas heat exchanger

- Dangerous conditions in gas furnaces

- Annual service of the gas furnace

- Repair procedures for gas furnaces

- Gas fireplace millivolt systems

- Oil furnace

- Setting gas input

- Quick tips for troubleshooting furnaces

- Troubleshoot

- Operation and troubleshoot furnace by manufacturer

- HVAC war stories blog

- Annual service of an oil furnace

- Oil furnace design

- Oil furnace troubleshoot

- Repair procedures for oil furnaces

- Gas code training

- Piping and connections

- FAG w pilot no fire

- Combustion analysis

- Electric furnace

- Air conditioner

- Refrigeration

- Heat Pump

- Boiler

- Ductwork design and troubleshoot

- Thermostats

- Diagnostic problems

- Tools

- Electric test meters

- Electrical diagram training

- Electrical symbols

- Single and 3 phase power systems

- Electric wiring solutions

- Transformer design and troubleshoot

- Electronic air cleaner

- Blowers and fans design & troubleshoot

- Humidity and humidifiers

- Furnace, Air Conditioner and part manuals

- Electric motors

- Run Capacitors

- Start capacitors

- Troubleshooting the capacitor

- Gas furnace short cycling

Electronic air cleaner design and troubleshoot

The electronic air cleaner uses high voltage to ionize dust particles so they can be attracted to oppositely charged metal plates. Somewhat similar to how static electricity attracts lint to clothing.

Most filter media catches particles if they are larger than certain sizes.

Electronic air cleaners will catch very small particles. Here is how it works:

Electronic air cleaners will catch very small particles. Here is how it works:

Ionizer

The small diameter wires on the left are called ionizer wires.

These are charged with high voltage to ionize the particles as they pass through. Air passes into the cleaner from this side first.

These wires are delicate as are most parts of the cell.

These are charged with high voltage to ionize the particles as they pass through. Air passes into the cleaner from this side first.

These wires are delicate as are most parts of the cell.

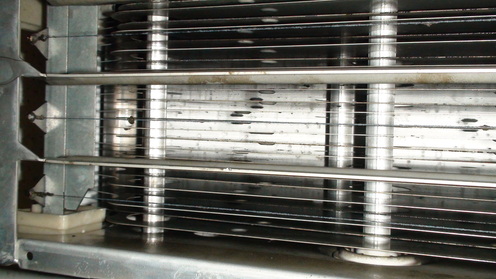

Collector

When the particles have been charged, they pass to the collector.

Here they attach to the collector plates. Note the collector plates are closer together than the ionizer section.

Most of the particles attach here on the plates.

Here they attach to the collector plates. Note the collector plates are closer together than the ionizer section.

Most of the particles attach here on the plates.

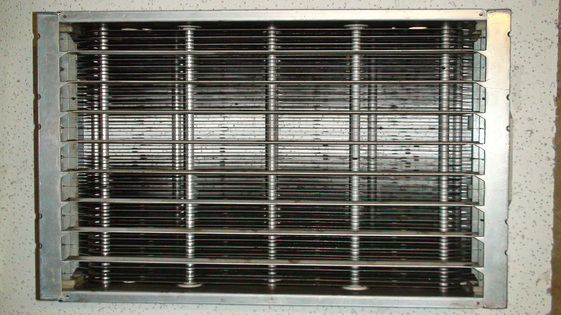

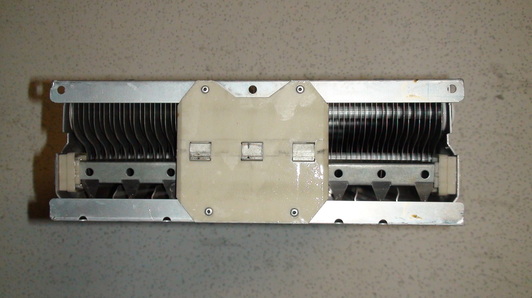

The whole collector

This is the entire cell as seen from the collector side.

The whole ionizer

This is the entire cell as seen from the ionizer side.

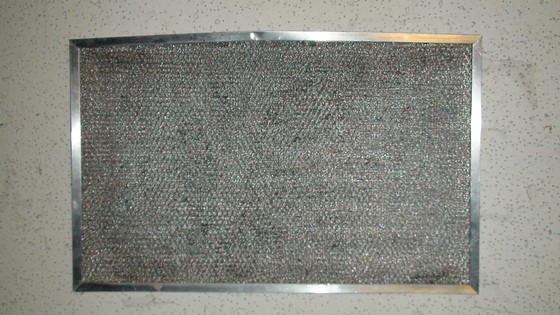

The pre filter

This a aluminum mesh pre filter. It is placed so that the air passes through it before going to the filter cells.

It is the part that plugs first. This part can be installed backwards in the housing, so be sure it is installed away from the furnace.

The cells seldom plug because of the wide spaces between them.

It is the part that plugs first. This part can be installed backwards in the housing, so be sure it is installed away from the furnace.

The cells seldom plug because of the wide spaces between them.

Contact plates

This end of the cell has contact plates that transfer power from the power head to the cells.

The cell must be installed with the contact plate toward the power head.

The cleaner housing is designed to not allow the cells to be installed backwards, but I have seen it done. There is an airflow arrow on the cell.

The cell must be installed with the contact plate toward the power head.

The cleaner housing is designed to not allow the cells to be installed backwards, but I have seen it done. There is an airflow arrow on the cell.

Contact plate troubleshoot.

These plates are mounted on the end of the cell. The strap on the left side of the plate transfers power to the plates.

If the cells are installed and the power turned on while they are wet, the straps wear excessively and will corrode.

This results in the plates arcing across. The unit usually makes a continuous sparking noise.

The plates are replaceable.

There is a kit available. The contact plates have their rivets removed and the cell is reversed and new rivets are used to mount the plates on the opposite end of the cell. The kit also has a replacement plastic handle for mounting on the other side of the cell. These cells are very expensive and great care should be used when handling them.

If the cells are installed and the power turned on while they are wet, the straps wear excessively and will corrode.

This results in the plates arcing across. The unit usually makes a continuous sparking noise.

The plates are replaceable.

There is a kit available. The contact plates have their rivets removed and the cell is reversed and new rivets are used to mount the plates on the opposite end of the cell. The kit also has a replacement plastic handle for mounting on the other side of the cell. These cells are very expensive and great care should be used when handling them.

Cleaning the cells.

The cells are usually much dirtier than they look. Strong detergent or a grease cleaner should be used. Do not use any type of brush on these cells. It is very easy to bend the plates or break the ionizing wires. Do not forget the pre filters. Rinse thoroughly. A pressure washer can be used however, keep the nozzle well away from the cell plates. The cells can be reinstalled and the fan left on to dry them. Do not forget to turn on the air cleaner after a few hours.

Below is a video demonstrating how to clean the electronic air cleaner cells.

Below is a video demonstrating how to clean the electronic air cleaner cells.

The front panel

The front panel is equipped with a tang on the top that fits into the head assembly. When removed, it shuts off the power to the unit. Also, on the bottom there is a red button to discharge the cells.

A quick check to see if the unit is operating is to press the red button while the fan is running. You should hear a spark.

A quick check to see if the unit is operating is to press the red button while the fan is running. You should hear a spark.

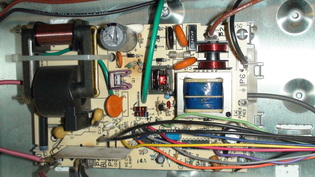

The powerhead

The powerhead is mounted on top of the cell housing. It contains all the electronics to operate the cleaner. The power switch and power light are shown.

Troubleshooting the Electronics

If, when the red button is pushed and the fan is running, there is no spark, Check the power supply. The light in the switch should be on. If the light stays off, remove one cell and check again, then put that cell back in and leave the other one in. If it works with one cell in, the other cell is shorted.

Sometimes the plates are bent over and shorting together. A very close visual check should find it. Look for white deposits on the collector plates.

If there is no indication of high voltage power, either the pressure switch has failed or the electronics have failed. While it is possible to diagnose the failure to either the pressure switch or the electronics, this may be a job for a professional.

Unit sparks all the time

First, clean the cells and pre filter. let the cells dry. If it still sparks, you can run the furnace with the fan cover off (the door switch will have to be taped shut) and look for the spark. Sometimes you will have to partially close the fan door to allow the pressure to allow the unit to come on.

Remember the plates could be very close to cause it to spark. Look closely. Back to home

Sometimes the plates are bent over and shorting together. A very close visual check should find it. Look for white deposits on the collector plates.

If there is no indication of high voltage power, either the pressure switch has failed or the electronics have failed. While it is possible to diagnose the failure to either the pressure switch or the electronics, this may be a job for a professional.

Unit sparks all the time

First, clean the cells and pre filter. let the cells dry. If it still sparks, you can run the furnace with the fan cover off (the door switch will have to be taped shut) and look for the spark. Sometimes you will have to partially close the fan door to allow the pressure to allow the unit to come on.

Remember the plates could be very close to cause it to spark. Look closely. Back to home