- Home

- For the homeowner

- Safety

- Definitions

- Gas furnace

- Some error codes for gas furnaces

- Service sheet for the gas furnace

- gas furnace design

- The gas heat exchanger

- Dangerous conditions in gas furnaces

- Annual service of the gas furnace

- Repair procedures for gas furnaces

- Gas fireplace millivolt systems

- Oil furnace

- Setting gas input

- Quick tips for troubleshooting furnaces

- Troubleshoot

- Operation and troubleshoot furnace by manufacturer

- HVAC war stories blog

- Annual service of an oil furnace

- Oil furnace design

- Oil furnace troubleshoot

- Repair procedures for oil furnaces

- Gas code training

- Piping and connections

- FAG w pilot no fire

- Combustion analysis

- Electric furnace

- Air conditioner

- Refrigeration

- Heat Pump

- Boiler

- Ductwork design and troubleshoot

- Thermostats

- Diagnostic problems

- Tools

- Electric test meters

- Electrical diagram training

- Electrical symbols

- Single and 3 phase power systems

- Electric wiring solutions

- Transformer design and troubleshoot

- Electronic air cleaner

- Blowers and fans design & troubleshoot

- Humidity and humidifiers

- Furnace, Air Conditioner and part manuals

- Electric motors

- Run Capacitors

- Start capacitors

- Troubleshooting the capacitor

- Gas furnace short cycling

Electric troubleshoot for pilot gas furnace no heat

In the pilot gas furnace, the gas supply is controlled by the combination gas valve. This is the load for the control circuit. In series with this device will be switches to control when the device comes on. In gas furnaces, typical switches would be the wall thermostat and and a limit control to prevent overheat. If power is available at the transformer, the thermostat should be checked. To check the thermostat, remove it from the wall. There should be a subase beneath it. There will be a minimum of 2 wires on the terminals. There should be a White wire connected to the "W" terminal, and there should be a Red wire connected to the "R" terminal. Place a jumper wire between the terminals. If the furnace fires the thermostat has failed.

If you have no luck there, there will be a limit with its probe in the airflow through the furnace. These are combination fan and limit switches that keep the furnace from overheating.

The wires to the gas valve will go through this switch. Jumper it out. If the furnace fires, the limit has failed or the furnace has overheated.

On some furnaces there will be other switches such as fusible links. They should be jumpered too.

If you find a limit or fusible link failed, it should not be bypassed. These are safety controls and bypassing them could easily cause a fire in the structure.

A replacement control should be purchased.

If you have no luck there, there will be a limit with its probe in the airflow through the furnace. These are combination fan and limit switches that keep the furnace from overheating.

The wires to the gas valve will go through this switch. Jumper it out. If the furnace fires, the limit has failed or the furnace has overheated.

On some furnaces there will be other switches such as fusible links. They should be jumpered too.

If you find a limit or fusible link failed, it should not be bypassed. These are safety controls and bypassing them could easily cause a fire in the structure.

A replacement control should be purchased.

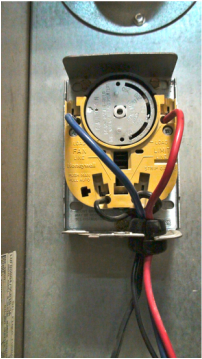

Fan and limit switch

The switch on the left has a limit switch terminals on the right and fan switch terminals on the left.

It is operated by the heat inside the furnace as sensed by the bimetal spiral in the probe. The dial in the middle is moved by the spiral bimetal.

There are adjustment pins for fan on temperature, fan off temperature. Troubleshooting this control in the fan mode consists of firing off the furnace for 2-3 min. If the fan does not come on during that time, a voltmeter should be placed across the left side terminals with the blue wire on top and black wire on bottom. If the voltmeter reads line voltage with the burner on for 2-3 min, the control has failed. When the furnace operates with no fan, the limit, on the right side of control with red wire on top and black on bottom, should shut off the burners after about 5 minutes.

If power is available through the fan switch, there is a problem with the fan motor.

It is operated by the heat inside the furnace as sensed by the bimetal spiral in the probe. The dial in the middle is moved by the spiral bimetal.

There are adjustment pins for fan on temperature, fan off temperature. Troubleshooting this control in the fan mode consists of firing off the furnace for 2-3 min. If the fan does not come on during that time, a voltmeter should be placed across the left side terminals with the blue wire on top and black wire on bottom. If the voltmeter reads line voltage with the burner on for 2-3 min, the control has failed. When the furnace operates with no fan, the limit, on the right side of control with red wire on top and black on bottom, should shut off the burners after about 5 minutes.

If power is available through the fan switch, there is a problem with the fan motor.

The direct drive blower with motor in the middle.

The fan motor should be running if power is available. A quick check of the motor is to touch the body of the motor after the furnace has been on for a while, careful, may be hot. If it is hot, power is available. Rotate the blower wheel. If it does not rotate easily, the bearings are failed. Motor must be replaced. If it is hot and it turns easily, check for a motor run capacitor.

The run capacitor

If this part on left is mounted on the blower housing, you have a run capacitor. If this part is failed, the motor usually won't run. The motor will overheat and the internal overload will shut off the motor.

It can be checked with a meter that has a capacitor test option. Alternately, it can be replaced, it is not a terribly expensive part. The capacitor has its size in microfarads and voltage printed on the side.

If this does not help, the motor windings have probably shorted.

If the motor is cold and power is available at the wires coming off the motor, the motor has an open. In either case, the motor has failed.

back to troubleshoot

It can be checked with a meter that has a capacitor test option. Alternately, it can be replaced, it is not a terribly expensive part. The capacitor has its size in microfarads and voltage printed on the side.

If this does not help, the motor windings have probably shorted.

If the motor is cold and power is available at the wires coming off the motor, the motor has an open. In either case, the motor has failed.

back to troubleshoot