- Home

- For the homeowner

- Safety

- Definitions

- Gas furnace

- Some error codes for gas furnaces

- Service sheet for the gas furnace

- gas furnace design

- The gas heat exchanger

- Dangerous conditions in gas furnaces

- Annual service of the gas furnace

- Repair procedures for gas furnaces

- Gas fireplace millivolt systems

- Oil furnace

- Setting gas input

- Quick tips for troubleshooting furnaces

- Troubleshoot

- Operation and troubleshoot furnace by manufacturer

- HVAC war stories blog

- Annual service of an oil furnace

- Oil furnace design

- Oil furnace troubleshoot

- Repair procedures for oil furnaces

- Gas code training

- Piping and connections

- FAG w pilot no fire

- Combustion analysis

- Electric furnace

- Air conditioner

- Refrigeration

- Heat Pump

- Boiler

- Ductwork design and troubleshoot

- Thermostats

- Diagnostic problems

- Tools

- Electric test meters

- Electrical diagram training

- Electrical symbols

- Single and 3 phase power systems

- Electric wiring solutions

- Transformer design and troubleshoot

- Electronic air cleaner

- Blowers and fans design & troubleshoot

- Humidity and humidifiers

- Furnace, Air Conditioner and part manuals

- Electric motors

- Run Capacitors

- Start capacitors

- Troubleshooting the capacitor

- Gas furnace short cycling

The oil furnace nozzle

The nozzle is a device used to atomize the fuel oil into very small droplets. The smaller the droplets, the better the oil burns. The oil is lit by a high temperature spark which vaporizes and heats a small amount of the oil. Once the spark lights some of the oil, the heat released vaporizes and lights the rest of the oil.

The pressure used to atomize the oil is critical to completely atomizing the oil. Most pumps run at a minimum of 100# with newer pumps running higher pressures.

The pressure used to atomize the oil is critical to completely atomizing the oil. Most pumps run at a minimum of 100# with newer pumps running higher pressures.

Nozzle spray

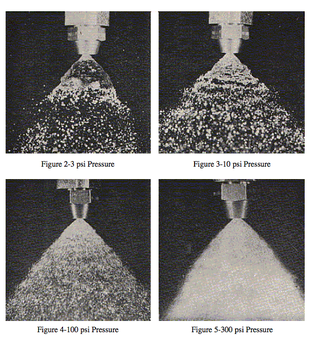

This an illustration of the nozzle at various pressures.

Note the droplets are smaller as the pressure increases.

The smaller the droplets the easier the oil evaporates.

The video below shows a nozzle at different pressures, showing the difference as the pressure increases.

Note the droplets are smaller as the pressure increases.

The smaller the droplets the easier the oil evaporates.

The video below shows a nozzle at different pressures, showing the difference as the pressure increases.

For further information on Delevan nozzles click here

For further information on Monarch nozzles click here

For further information on Danfoss nozzles click here

Nozzles are rated for oil flow at gallons per hour at 100# pressure.

Many newer burners run at higher than the 100# pressure.

Below there is a chart that gives approximate gallons per hour of varying pressures higher than 100#.

Many newer burners run at higher than the 100# pressure.

Below there is a chart that gives approximate gallons per hour of varying pressures higher than 100#.

Your browser does not support viewing this document. Click here to download the document.