- Home

- For the homeowner

- Safety

- Definitions

- Gas furnace

- Some error codes for gas furnaces

- Service sheet for the gas furnace

- gas furnace design

- The gas heat exchanger

- Dangerous conditions in gas furnaces

- Annual service of the gas furnace

- Repair procedures for gas furnaces

- Gas fireplace millivolt systems

- Oil furnace

- Setting gas input

- Quick tips for troubleshooting furnaces

- Troubleshoot

- Operation and troubleshoot furnace by manufacturer

- HVAC war stories blog

- Annual service of an oil furnace

- Oil furnace design

- Oil furnace troubleshoot

- Repair procedures for oil furnaces

- Gas code training

- Piping and connections

- FAG w pilot no fire

- Combustion analysis

- Electric furnace

- Air conditioner

- Refrigeration

- Heat Pump

- Boiler

- Ductwork design and troubleshoot

- Thermostats

- Diagnostic problems

- Tools

- Electric test meters

- Electrical diagram training

- Electrical symbols

- Single and 3 phase power systems

- Electric wiring solutions

- Transformer design and troubleshoot

- Electronic air cleaner

- Blowers and fans design & troubleshoot

- Humidity and humidifiers

- Furnace, Air Conditioner and part manuals

- Electric motors

- Run Capacitors

- Start capacitors

- Troubleshooting the capacitor

- Gas furnace short cycling

Soot problems in oil furnaces

Oil furnaces use a flammable fuel. leaks left can cause fires. Things like puffback are usually not devastating explosions but can cause a fire or extensive property damage. There are also lethal voltages involved. Know your limits.

|

One of the biggest problems with oil furnaces is sooting up. If the burner is not regularly serviced (or sometimes even if it is) the combustion can get dirty.

Soot buildup is not normal for an oil furnace. Soot buildup comes from incomplete combustion. Symtoms are: Burned oil smell in the structure. A rumbling noise from the furnace on startup, especially when the furnace has been off for a long time. Smoke in the structure. Intermittent flame failure shut down. To determine where the failure is: look for the 2 small holes as seen on the left. These are sampling holes to check pressure. The bottom hole is in the combustion chamber and senses pressure over the fire. The one on the top senses pressure in the smoke pipe. |

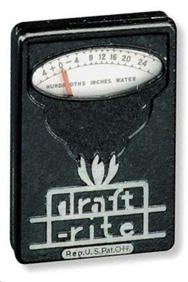

The draft gauge

Above are 2 types of draft gauges. They have probes used to sense the negative pressure in the furnace. The probe is inserted into the sensing holes to determine how much negative pressure is in the sensed area.

Using the draft gauge:

These tools must be leveled prior to use. When the probe is placed in the lower hole in the pic it is sensing negative pressure over the fire. When placed in the upper hole it is sensing negative pressure in the smoke pipe.

Now, we need to determine what the readings mean.

The negative pressure over the fire should be -.02 in wc. If the pressure is less or in the positive range, there is a blockage in either the heat exchanger or the chimney.

Next, check the smoke pipe. The negative pressure here should be -.03 or 4. If the pressure is less or positive here, the chimney is blocked. As a double check, close the barometric damper and recheck. If the pressure does not change there is a blockage. If it does change to normal pressure, the weights on the damper need to be adjusted.

If you do not have these tools, the best you can do is check for smoke puffs on startup and look for soot in the smoke pipe.

If the chimney is plugged clean the chimney.

If the pressure is ok in the smoke pipe, but not overfire, the heat exchanger is plugged.

This is more problematic. The heat exchanger needs a high volume vacuum cleaning. A shop vac will probably not complete this job.

In either case, the it must be taken care of. If left, you will probably have a puffback. This is a term for a small explosion inside the combustion chamber. It will send soot throughout the structure and is much worse than it sounds.

Using the draft gauge:

These tools must be leveled prior to use. When the probe is placed in the lower hole in the pic it is sensing negative pressure over the fire. When placed in the upper hole it is sensing negative pressure in the smoke pipe.

Now, we need to determine what the readings mean.

The negative pressure over the fire should be -.02 in wc. If the pressure is less or in the positive range, there is a blockage in either the heat exchanger or the chimney.

Next, check the smoke pipe. The negative pressure here should be -.03 or 4. If the pressure is less or positive here, the chimney is blocked. As a double check, close the barometric damper and recheck. If the pressure does not change there is a blockage. If it does change to normal pressure, the weights on the damper need to be adjusted.

If you do not have these tools, the best you can do is check for smoke puffs on startup and look for soot in the smoke pipe.

If the chimney is plugged clean the chimney.

If the pressure is ok in the smoke pipe, but not overfire, the heat exchanger is plugged.

This is more problematic. The heat exchanger needs a high volume vacuum cleaning. A shop vac will probably not complete this job.

In either case, the it must be taken care of. If left, you will probably have a puffback. This is a term for a small explosion inside the combustion chamber. It will send soot throughout the structure and is much worse than it sounds.

If a draft gauge is not available

If you do not have a draft gauge you can still detect draft problems by placing your hand near the sampling hole above the combustion chamber. If you feel hot air coming out of the hole, there is a blockage between the combustion chamber and the exit outside of the house.

Next, do the same at the sampling hole in the smoke pipe. If there is hot air coming out there, the problem is in the smoke pipe or the chimney. If the is no hot air, the problem is in the heat exchanger.

On the left, the top hole is the smoke pipe sampling hole.

The one below is the overfire draft.

For a look at the procedure for cleaning the heat exchanger check the videos below. Using a shop vac is not recommended but can be used in a pinch.

Back

Next, do the same at the sampling hole in the smoke pipe. If there is hot air coming out there, the problem is in the smoke pipe or the chimney. If the is no hot air, the problem is in the heat exchanger.

On the left, the top hole is the smoke pipe sampling hole.

The one below is the overfire draft.

For a look at the procedure for cleaning the heat exchanger check the videos below. Using a shop vac is not recommended but can be used in a pinch.

Back