- Home

- For the homeowner

- Safety

- Definitions

- Gas furnace

- Some error codes for gas furnaces

- Service sheet for the gas furnace

- gas furnace design

- The gas heat exchanger

- Dangerous conditions in gas furnaces

- Annual service of the gas furnace

- Repair procedures for gas furnaces

- Gas fireplace millivolt systems

- Oil furnace

- Setting gas input

- Quick tips for troubleshooting furnaces

- Troubleshoot

- Operation and troubleshoot furnace by manufacturer

- HVAC war stories blog

- Annual service of an oil furnace

- Oil furnace design

- Oil furnace troubleshoot

- Repair procedures for oil furnaces

- Gas code training

- Piping and connections

- FAG w pilot no fire

- Combustion analysis

- Electric furnace

- Air conditioner

- Refrigeration

- Heat Pump

- Boiler

- Ductwork design and troubleshoot

- Thermostats

- Diagnostic problems

- Tools

- Electric test meters

- Electrical diagram training

- Electrical symbols

- Single and 3 phase power systems

- Electric wiring solutions

- Transformer design and troubleshoot

- Electronic air cleaner

- Blowers and fans design & troubleshoot

- Humidity and humidifiers

- Furnace, Air Conditioner and part manuals

- Electric motors

- Run Capacitors

- Start capacitors

- Troubleshooting the capacitor

- Gas furnace short cycling

Gas furnace short cycling

|

|

|

Furnace short cycling is one of the most common problems with furnace operation.

Short cycling means the furnace starts but will not stay on long enough to bring the structure up to the set point temperature.

If the burner starts and runs for 4 to 7 seconds and it was made in the last 25 years, there is probably a flame proving problem.

The most common of these is the flame rod failing to sense the flame. What is happening here is the gas is supplied to the burners and the burners light. Modern furnaces must prove that the flame has come on within 4 to 7 seconds or the gas is shut off and the unit tries again. This happens 3 times, then it shuts down on a flame failure error code. The first action should be to clean the flame rod.

Short cycling means the furnace starts but will not stay on long enough to bring the structure up to the set point temperature.

If the burner starts and runs for 4 to 7 seconds and it was made in the last 25 years, there is probably a flame proving problem.

The most common of these is the flame rod failing to sense the flame. What is happening here is the gas is supplied to the burners and the burners light. Modern furnaces must prove that the flame has come on within 4 to 7 seconds or the gas is shut off and the unit tries again. This happens 3 times, then it shuts down on a flame failure error code. The first action should be to clean the flame rod.

Location of flame rod

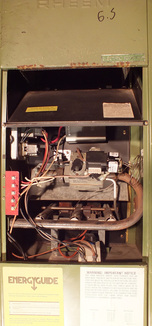

In this furnace, the flame rod extends into the flame from above. This is an 80% efficient furnace and the burners are usually on the bottom of the furnace section.

When the burners light, the flame rod senses the flame by flame rectification. The flame rod is simply a stainless steel rod placed in the flame.

Contaminates attach to the rod and inhibit its ability to sense.

Cleaning it with steel wool or sandpaper will bring its sensitivity back. Do not get overly aggressive when cleaning.

Reasonable care should be taken during cleaning. If the white ceramic is cracked, it will have to be replaced.

Do not bend the rod in an attempt to increase its sensitivity. This will not help and many of the rods are hardened and will break if too much tension is placed on them. Remember, there is nothing special about the rod. It is just a piece of stainless steel.

When troubleshooting for flame sense problems, the sequence should be: watch the burners light, if all burners light normally, clean the flame rod. Certainly check the wiring terminals. They should be tight. Any push on terminals that are loose should be crimped. Check the terminal where the flame rod wire is attached to the IFC. Check voltage supply. If the supply voltage supply is within 10% of the rated voltage (found on the model plate) it is ok. If all these things have been checked, consideration should be given to replacement of the IFC. The IFC is the most expensive part of this part of the furnace, and all other possibilities should be eliminated first.

The video below covers how to clean the flame rod.

When the burners light, the flame rod senses the flame by flame rectification. The flame rod is simply a stainless steel rod placed in the flame.

Contaminates attach to the rod and inhibit its ability to sense.

Cleaning it with steel wool or sandpaper will bring its sensitivity back. Do not get overly aggressive when cleaning.

Reasonable care should be taken during cleaning. If the white ceramic is cracked, it will have to be replaced.

Do not bend the rod in an attempt to increase its sensitivity. This will not help and many of the rods are hardened and will break if too much tension is placed on them. Remember, there is nothing special about the rod. It is just a piece of stainless steel.

When troubleshooting for flame sense problems, the sequence should be: watch the burners light, if all burners light normally, clean the flame rod. Certainly check the wiring terminals. They should be tight. Any push on terminals that are loose should be crimped. Check the terminal where the flame rod wire is attached to the IFC. Check voltage supply. If the supply voltage supply is within 10% of the rated voltage (found on the model plate) it is ok. If all these things have been checked, consideration should be given to replacement of the IFC. The IFC is the most expensive part of this part of the furnace, and all other possibilities should be eliminated first.

The video below covers how to clean the flame rod.

There are few tools needed to clean the flame rod. However, a thorough troubleshoot includes testing the flame rod sensing. For this you will need a meter that reads DC microamps. The meter probes are placed in series between the terminal of the flame rod and the wire connected to it. The readings can be specific for each furnace, but most will prove flame at 1/2 microamp, and normal is between 2 and 4. The video below shows methods to check the flame rod microamps

Short cycling can also mean the furnace is overheating. There are one or more high temperature limits on the furnace to protect the furnace from burning up.

The symptom of overheat will be the furnace will light and run normally for 3 to 10 minutes, then the burner will shut off. If the fan has come on, it should stay on. The burner may come on again after 5 to 10 minutes. Look for plugged filter, Dirty blower wheel, ductwork problems.

The symptom of overheat will be the furnace will light and run normally for 3 to 10 minutes, then the burner will shut off. If the fan has come on, it should stay on. The burner may come on again after 5 to 10 minutes. Look for plugged filter, Dirty blower wheel, ductwork problems.