- Home

- For the homeowner

- Safety

- Definitions

- Gas furnace

- Some error codes for gas furnaces

- Service sheet for the gas furnace

- gas furnace design

- The gas heat exchanger

- Dangerous conditions in gas furnaces

- Annual service of the gas furnace

- Repair procedures for gas furnaces

- Gas fireplace millivolt systems

- Oil furnace

- Setting gas input

- Quick tips for troubleshooting furnaces

- Troubleshoot

- Operation and troubleshoot furnace by manufacturer

- HVAC war stories blog

- Annual service of an oil furnace

- Oil furnace design

- Oil furnace troubleshoot

- Repair procedures for oil furnaces

- Gas code training

- Piping and connections

- FAG w pilot no fire

- Combustion analysis

- Electric furnace

- Air conditioner

- Refrigeration

- Heat Pump

- Boiler

- Ductwork design and troubleshoot

- Thermostats

- Diagnostic problems

- Tools

- Electric test meters

- Electrical diagram training

- Electrical symbols

- Single and 3 phase power systems

- Electric wiring solutions

- Transformer design and troubleshoot

- Electronic air cleaner

- Blowers and fans design & troubleshoot

- Humidity and humidifiers

- Furnace, Air Conditioner and part manuals

- Electric motors

- Run Capacitors

- Start capacitors

- Troubleshooting the capacitor

- Gas furnace short cycling

High temperature limit problems on gas furnaces

When troubleshooting, understand you are working with potentially lethal voltages and a highly flammable gas. If you do not have the ability to do these operations safely, do not attempt them.

Limit switch codes

If the furnace failure code indicates an "open limit" or "open high temperature switch" or "open rollout switch", it is probable that the furnace has overheated.

Limit switches turn off the burner and turn on the circulating fan if there is a high temperature condition in the furnace.

|

|

There is a difference between a limit switch and a rollout switch.

The limit switch shuts off the burner when the temperature exceeds a preset temperature. When the temperature reduces to normal, the burner will come back on. The most common reason for limits to open is a plugged filter or a dirty blower wheel. On the left are some high temperature limits used in furnaces. Rollout switches and high temperature fuses are different from limit switches in that when they open, they will not close again unless reset as in the case of the rollout switch or replaced as in the case of the high temperature fuse. Some of these parts are shown on the left. They will be mounted near where the flame may rollout the front of the furnace due to venting blockages, heat exchanger cracks or heat exchanger blockages.

Below is a video showing a flame rollout. |

Below is a video on assorted furnace temperature controls

Flame failure code with burners lighting for a short time.

If the burners come on for 4-7 seconds then shut off, there is a problem with flame sensing. Most units will light 3 times, then go into hard lockout.

Many of the failures of modern furnaces can be traced to simple maintenance.

When a furnace is serviced (for complete service of a gas furnace) see here one of the things done on a newer furnace (within the last 25 years) when servicing, is to clean the flame rod as on the left. Symptoms of flame rod failure to sense are intermittent flame failure resulting in occasional flame failure codes on the IFC. When the power is turned off and back on, it usually starts.

As one of the attributes of the IFC is to attempt restart after 1 hour if there is a flame failure, this sometimes seems to be a very intermittent and frustrating problem to the owner.

Many parts have been replaced when the only problem is the cleanliness of the flame rod.

In some cases, if the input gas pressure is very low, there may not be enough flame to sense the flame.

If, when the burners light, not all of the burners light, there will of course be no flame sense.

If this happens, first remove the burners and clean them. If this is not effective, a thorough check of the furnace heat exchanger should be done. A carbon monoxide check should be considered. From the front of the furnace, the flame should move smoothly into the heat exchanger. Any rollout of the flame could cause flame sense problems.

Many of the failures of modern furnaces can be traced to simple maintenance.

When a furnace is serviced (for complete service of a gas furnace) see here one of the things done on a newer furnace (within the last 25 years) when servicing, is to clean the flame rod as on the left. Symptoms of flame rod failure to sense are intermittent flame failure resulting in occasional flame failure codes on the IFC. When the power is turned off and back on, it usually starts.

As one of the attributes of the IFC is to attempt restart after 1 hour if there is a flame failure, this sometimes seems to be a very intermittent and frustrating problem to the owner.

Many parts have been replaced when the only problem is the cleanliness of the flame rod.

In some cases, if the input gas pressure is very low, there may not be enough flame to sense the flame.

If, when the burners light, not all of the burners light, there will of course be no flame sense.

If this happens, first remove the burners and clean them. If this is not effective, a thorough check of the furnace heat exchanger should be done. A carbon monoxide check should be considered. From the front of the furnace, the flame should move smoothly into the heat exchanger. Any rollout of the flame could cause flame sense problems.

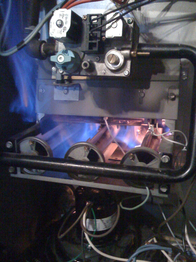

Flame rollout

This is an example of flame rollout. As you can see, the flame can burn wires, damage the gas valve (center top) or cause a fire.

Below are examples of a rollout switch (below left) and a limit switch (below right) as installed in the furnace.

If you see an error code for high temperature limit, usually limit switches and rollout switches are wired in series, so if one of the limits opens the burners will shut down.

The limit shown on the right senses the temperature inside the furnace. When it shuts off due to high temperature, you should check filter condition first. A dirty blower wheel could also be the problem.

This limit should reset on its own when the temperature returns to normal. Occasionally, the limit will not reset on its own. This is usually because the low air flow that caused the problem has continued for too long. The switch can be removed and struck against the furnace body lightly. This may break loose the contacts inside. If this solves the problem do not trust the switch not to fail again. Replace it.

The rollout switch will not reset if it opens. The reason it will not reset is if it has opened, there is an unsafe condition in the furnace. It can be reset manually by pushing the button on the center. I do not recommend resetting the rollout switch without finding the reason for the failure. Rollout means the switch has been subject to high temperatures as in flame rolling out the front of the furnace. This could be due to a heat exchanger failure. The unit could also have been over fired. Either way, find out the problem before proceeding. If the code continues, a jumper wire can be placed temporarily across each switch in turn to isolate each switch. When you place a jumper across a limit, the power should be off. Then turn on the power and see if the unit starts.

If the unit starts, you have found the problem. DO NOT leave a jumper across any safety control permanently. It is only for testing and the equipment should be watched closely for overheat.

If all these tests fail to isolate the problem and the code continues, check all wiring connections for tight.

At this point the IFC appears to have failed. As the most expensive part of this part of the furnace, be sure all other parts have been thoroughly checked.

If you see an error code for high temperature limit, usually limit switches and rollout switches are wired in series, so if one of the limits opens the burners will shut down.

The limit shown on the right senses the temperature inside the furnace. When it shuts off due to high temperature, you should check filter condition first. A dirty blower wheel could also be the problem.

This limit should reset on its own when the temperature returns to normal. Occasionally, the limit will not reset on its own. This is usually because the low air flow that caused the problem has continued for too long. The switch can be removed and struck against the furnace body lightly. This may break loose the contacts inside. If this solves the problem do not trust the switch not to fail again. Replace it.

The rollout switch will not reset if it opens. The reason it will not reset is if it has opened, there is an unsafe condition in the furnace. It can be reset manually by pushing the button on the center. I do not recommend resetting the rollout switch without finding the reason for the failure. Rollout means the switch has been subject to high temperatures as in flame rolling out the front of the furnace. This could be due to a heat exchanger failure. The unit could also have been over fired. Either way, find out the problem before proceeding. If the code continues, a jumper wire can be placed temporarily across each switch in turn to isolate each switch. When you place a jumper across a limit, the power should be off. Then turn on the power and see if the unit starts.

If the unit starts, you have found the problem. DO NOT leave a jumper across any safety control permanently. It is only for testing and the equipment should be watched closely for overheat.

If all these tests fail to isolate the problem and the code continues, check all wiring connections for tight.

At this point the IFC appears to have failed. As the most expensive part of this part of the furnace, be sure all other parts have been thoroughly checked.

The blower below could be the cause of limiting out of the furnace

This is the result of no filter in the furnace or a plugged filter.

It requires thorough cleaning by disassembly and cleaning the blower wheel with strong detergent or power wash. The motor (center) should not get water on it. Clean it with a brush.

It requires thorough cleaning by disassembly and cleaning the blower wheel with strong detergent or power wash. The motor (center) should not get water on it. Clean it with a brush.