- Home

- For the homeowner

- Safety

- Definitions

- Gas furnace

- Some error codes for gas furnaces

- Service sheet for the gas furnace

- gas furnace design

- The gas heat exchanger

- Dangerous conditions in gas furnaces

- Annual service of the gas furnace

- Repair procedures for gas furnaces

- Gas fireplace millivolt systems

- Oil furnace

- Setting gas input

- Quick tips for troubleshooting furnaces

- Troubleshoot

- Operation and troubleshoot furnace by manufacturer

- HVAC war stories blog

- Annual service of an oil furnace

- Oil furnace design

- Oil furnace troubleshoot

- Repair procedures for oil furnaces

- Gas code training

- Piping and connections

- FAG w pilot no fire

- Combustion analysis

- Electric furnace

- Air conditioner

- Refrigeration

- Heat Pump

- Boiler

- Ductwork design and troubleshoot

- Thermostats

- Diagnostic problems

- Tools

- Electric test meters

- Electrical diagram training

- Electrical symbols

- Single and 3 phase power systems

- Electric wiring solutions

- Transformer design and troubleshoot

- Electronic air cleaner

- Blowers and fans design & troubleshoot

- Humidity and humidifiers

- Furnace, Air Conditioner and part manuals

- Electric motors

- Run Capacitors

- Start capacitors

- Troubleshooting the capacitor

- Gas furnace short cycling

Pilot light furnaces with a spark ignitor for the pilot

The standing pilot could not always be depended upon to stay on. Wind conditions, or building pressures could blow out the pilot. To keep the pilot on, the 2 wire pilot assembly was made. A bimetal strip located near the pilot burner is kept warm. That keeps open a switch. If the pilot blows out, the switch closes and starts a spark ignitor that relights the pilot. These units were primarily used on rooftop units that are exposed to wind conditions.

The video below covers this pilot assembly.

The video below covers this pilot assembly.

Carrier, Bryant, Day Night, and Payne spark ignitors

The standing pilot ignition system had one glaring deficiency. The pilot gas has to be supplied continuously. That means the unit is always using fuel.

One of the earliest methods of eliminating this fuel usage was the intermittent pilot.

When there is no call for heat, there is no pilot burning. On a call for heat, the pilot is lit, usually by a spark or hot stick. The pilot must then be proved. This means some type of circuit that insures that the pilot has lit before turning on main gas.

The pilot assembly above is one method of pilot proving. This unit uses a bimetal as the 2 wire does. However, the switch actuated by the bimetal is a single pole double throw switch. When in the deenergized position, it will start the spark ignitor and the pilot gas. However this switch will not allow main gas to come on unless it is in the energized position.

The video below describes this pilot assembly.

One of the earliest methods of eliminating this fuel usage was the intermittent pilot.

When there is no call for heat, there is no pilot burning. On a call for heat, the pilot is lit, usually by a spark or hot stick. The pilot must then be proved. This means some type of circuit that insures that the pilot has lit before turning on main gas.

The pilot assembly above is one method of pilot proving. This unit uses a bimetal as the 2 wire does. However, the switch actuated by the bimetal is a single pole double throw switch. When in the deenergized position, it will start the spark ignitor and the pilot gas. However this switch will not allow main gas to come on unless it is in the energized position.

The video below describes this pilot assembly.

The video below gives a view of how the pilot assembly operates.

The video below covers a particular failure related to the pilot assembly that is common with this system.

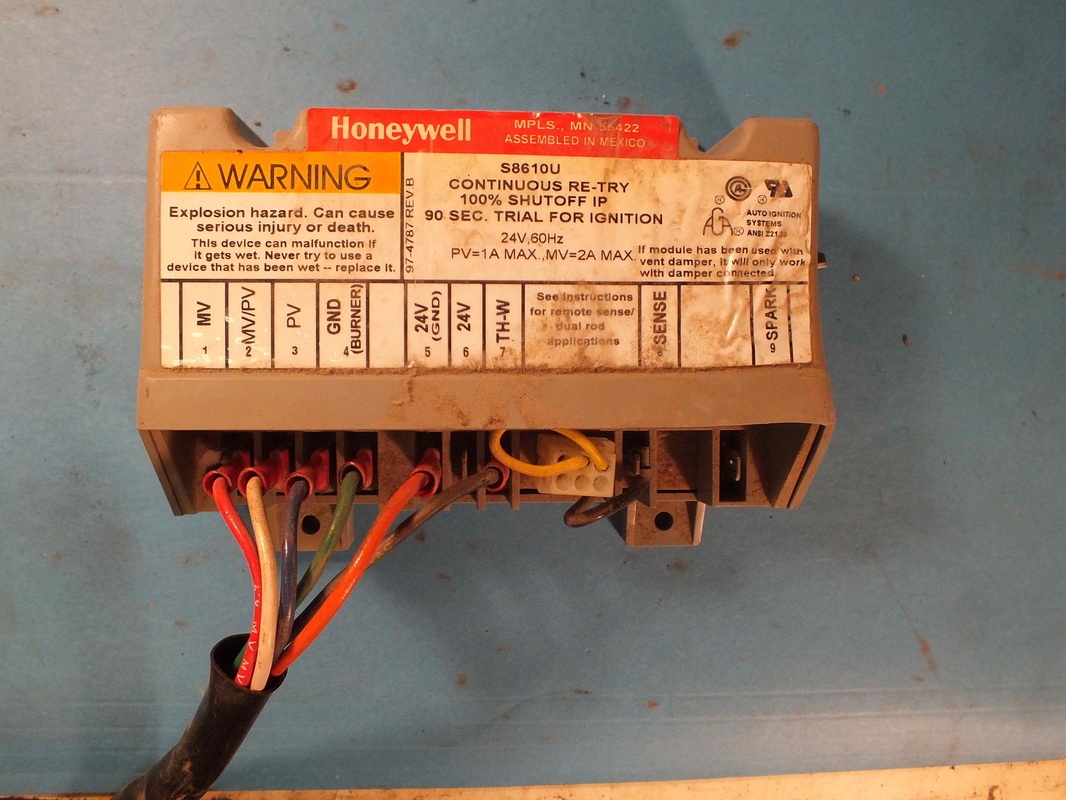

Electronic spark pilot ignition controls

Some furnaces use an electronic control light the pilot, prove the pilot has lit and turn on main gas.

These controls had some advantages compared to the electric pilot assemblies

shown above.

They could be used with standard pilot burners.

In the early 1980s, these were used sometimes as retrofits to older furnaces to reduce fuel usage. Also some utilities subsidized these installations.

These controls had some advantages compared to the electric pilot assemblies

shown above.

They could be used with standard pilot burners.

In the early 1980s, these were used sometimes as retrofits to older furnaces to reduce fuel usage. Also some utilities subsidized these installations.